By Krosino | 17 March 2023 | 0 Comments

What kind of parts could be machined by laser cutting?

CNC LASER CUTTING

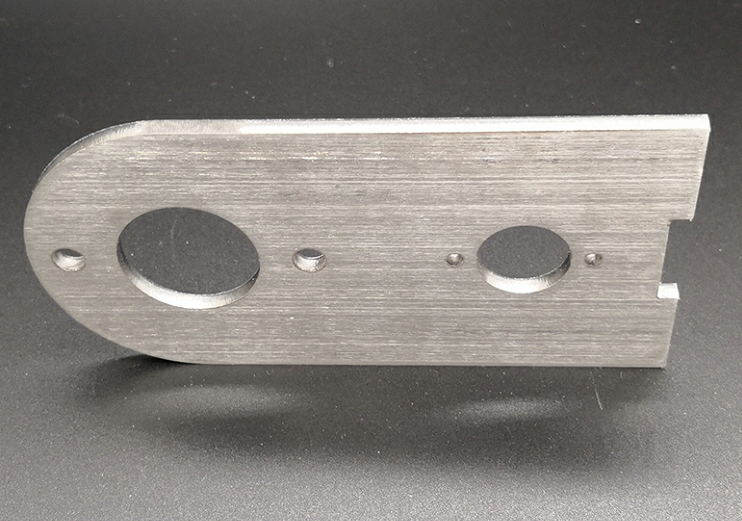

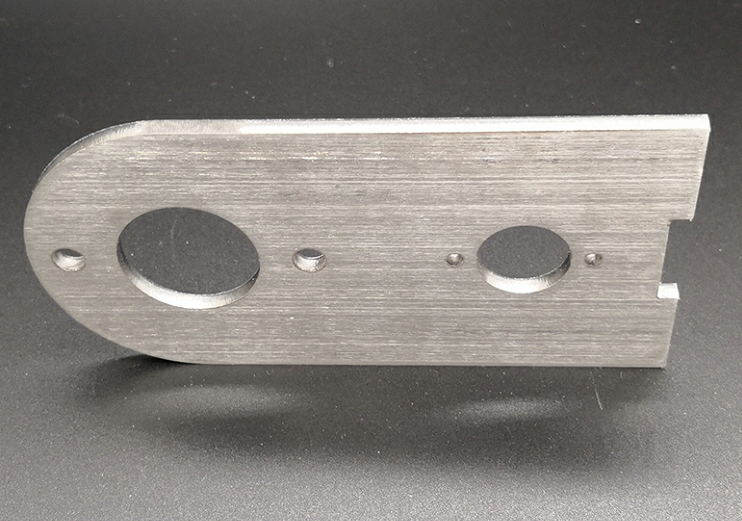

KROSINO offers custom CNC laser services for different metal parts. A CNC laser cutter is a piece of computer numerical control (CNC) equipment that uses a focused, high-powered laser beam to mark, cut, or engrave a material to form custom shapes. Its unique design and operation make it highly accurate, especially when cutting intricate shapes and small holes. Whether you need prototypes or product parts, our experienced teams can provide them with high standards and cost-effectiveness. We also have many surface finish options so that your machined part is exactly what you need it to be..

Advantages&Application

of LASER CUTTING

ADVANTAGE:

>Reliable and fast machinery for rapid turnaround

>Uses less energy when cutting – using nitrogen, oxygen, air

>Cuts through the thickest of metals – including mild steel

>Cut complex shapes with precise detail

>Non-wearing for a flawless edge finish

APPLICATION:

Laser cutting is most commonly used in the automotive, die, mold, tool, jewelry, and medical industries. It can be used to create parts for medical devices, computers and electronics, and much more. Materials that are difficult or impossible to cut using other methods make excellent candidates for laser cutting.

>Reliable and fast machinery for rapid turnaround

>Uses less energy when cutting – using nitrogen, oxygen, air

>Cuts through the thickest of metals – including mild steel

>Cut complex shapes with precise detail

>Non-wearing for a flawless edge finish

APPLICATION:

Laser cutting is most commonly used in the automotive, die, mold, tool, jewelry, and medical industries. It can be used to create parts for medical devices, computers and electronics, and much more. Materials that are difficult or impossible to cut using other methods make excellent candidates for laser cutting.

What Is laser cutting?

Material Comparison Guide

Choose from hundreds of manufacturing materials including various grades of thermoplastics, metals, and elastomers.

When selecting a material, consider the material properties, manufacturability characteristics, cosmetic appearance, and cost.

ALUMINUM: AL6061,AL6063,AL6082,AL7075,AL5052 ,ETC.

STAINLESS STEEL: 201SS,301SS,303SS,SUS304,316SS,2205 ,ETC.

STEEL: Q235,4140,4340,20#,45# ,ETC.

Finish: Clear Anodized,Color Anodized,Sandblast ,Chemical Film,Brushing,Polishing,Chorming,Heat treatment,Polishing,Passivating,Laser engraving,Brushing,Electrophoresis,Powder Coated,Zinc Plating,Oxide Black,Nickel Plating,Chrome Plating,Heat Treatment

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES