CNC Machining Services

Looking for a competitive advantage, rapid turnaround supplier for your CNC machining project? KROSINO is expert in CNC machining service in China for both prototypes and machined parts of end-use.

We offer a wide range of CNC machining services including milling and turning of various materials, as well as drilling, stamping, laser cutting, and wire EDM.

Our high strict production process, combined with professional experiences and advanced CNC machines ensures your parts are made right the first time, every time.

GET AN INSTANT QUOTE | CNC MACHINING PARTS

Choose a Realiable Supplier

On Demand CNC Machining Services

Make to order from 1 to 10,00 pieces on demand

Tight tolerance ±0.01mm Surface roughness Ra0.2μm

One-to-one service support

Flexible payment(L/C,TT,Paypal,Western Union,Cash)

Quick response within 2 hours

Quick quote within 12 hours

What We Good At CNC Machining Processes

KROSINO IS EXPERT IN CNC MILLING | CNC TURNING|LASER CUTTING|SHEET METAL|WIRE EDM.

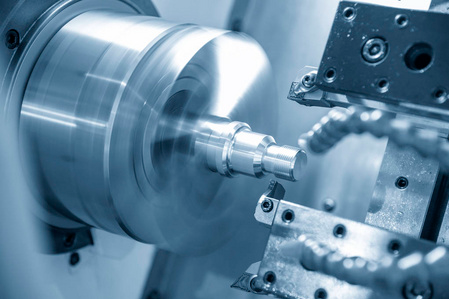

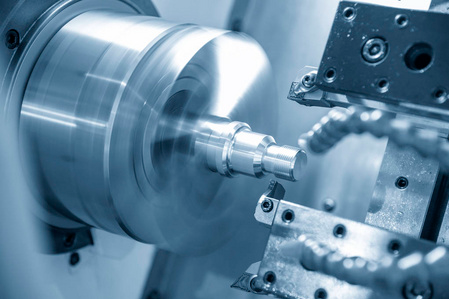

CNC MILLING

CNC milling is a subtractive manufacturing method that uses a cutting tool to moves and rotate to remove material. CNC mills can be used for cutting and machining operations of various plastic and metal materials. It is suitable for any industry that requires precision components and is also an ideal tool for making molds.

LEARN MORE about CNC MILLING

LASER CUTTING

a thermal process in which a focused laser beam is used to melt material in a localised area. A co-axial gas jet is used to eject the molten material and create a kerf. A continuous cut is produced by moving the laser beam or workpiece under CNC control.

Read more

Customers We Serve

KROSINO provides excellent global services and has a large, rapidly growing customer base. Our customers are spread around the world and come from a wide variety of industries. It covers from independent inventors or designers to large scale Industrial, Commercial, Medical, Automotive,Drones and some other companies. We will always do our best to meet your design and manufacturing needs to help your ideas come to life.

CNC TURNING

CNC turning removes material by contacting a cutter with the high-speed rotating workpiece and is usually used to create round or tubular shapes. The CNC turning process allows the generation of complex external geometries and internal holes, including the machining of various threads.

LEARN MORE ABOUT CNC turning

SHEET METALSheet metal processing is called sheet metal processing. For example, the use of plate to make chimneys, iron drums, fuel tank pots, ventilation pipes, elbows,advertising word ,computer Chassis,Machine cover panel and so on.The main procedures are shearing, bending buckle edge, bending molding, welding, riveting and so on, which requires certain geometric knowledge. Sheet metal parts are thin plate hardware parts, that is, parts that can be machined by stamping, bending, drawing and so on. EXPLORE MORE

Why Choose Krosino's CNC Machining Service ?

__________

Precision,Quality and affordability at any volume.Our teams give a quick feedback to accommodate your requirements.

Experienced Teams with Rich Expertise One to One Collaboration&Proactive Advanced In-house Equipments

High Complexity Machining Capability Competitive Pricing In The Industries More Flexible Payment ChoicesQuick Samples Machining Service Over 100 Cooperative Partners Quote Without Minimum Order Quantity

FROM CNC PROTOTYPING TO LOW-VOLUME PRODUCTION

————————————

We Offer A Differentiated Custom Machining Service

|Prototype Machining for Design Verification and Engineering Testing|

Prototyping is the process of creating metal parts through CNC processing. It allows your design team to closely simulate the appearance, function, and material properties of the final product. Moreover, testing the suitability and manufacturability of components is help to prove and perfect the design.

Krosino offers professional CNC services to ensure quality and accuracy, with a commitment to fast delivery.

________________________________________________________________________________________________________

|Custom Machining for Low-volume Production of End-use Parts|

The advantages of CNC machining are particularly well suited to the requirements of low-volume production runs of custom parts. Its accuracy and repeatability, flexible processes, as well as a wide range of material options help bring products to market faster.

Need 1 or 10,000 custom machined parts? Krosino have the capability and experience to provide efficient custom CNC machining services at a reasonable price.

CNC Machining Materials & Finishes

There are a wide variety of materials that can be machined using CNC technology, KROSINO provides CNC machining quotes for more than 25 kinds of materials. In terms of finishes, various types of surface finishes can be applied to CNC machined parts.

-Metal: Aluminum, Steel, Stainless Steel, Brass, Bronze, Titanium Alloy, Zinc Alloy.

-Carbon fiber:T300,T600,T700,T800 and T1000.

-Plastic: POM(Acetal / Delrin),ABS, PC, PMMA(Acrylic), PA(Nylon), PP, PVC, HDPE, PPS, PEEK.

-Finishes: We support one-stop CNC machining surface finishing to meet the visual and functional requirements of any design. Including sandblasting, anodizing,laser engraving,mirror polishing, painting, printing, laser etching, electroplating, powder coating, etc.

|CNC Metal Machining

Whether it is prototypes or end-use parts, our mastery of CNC metal machining techniques helps us to achieve tighter tolerances, faster turnaround times, and more challenging manufacturing projects.

products display

|CNC Carbon Fiber Machining

Carbon fiber material is very common used in recent years.

Krosino have cnc engraving and milling machine,heat press machine cutting machine,molding machine and shearing machine that could supply different kinds of carbon fiber material to process your parts such as drones frame panel,automative machine board,car board.

PRODUCTS DISPLAY

|CNC Plastic Machining

A variety of engineering-grade materials can be used for CNC plastic machining. The machined plastic parts are 100% functional and able to be mechanically tested.

PRODUCTS DISPLAY

The Ordering Process for cNC Machining Quotes

In Just 3 Steps

1.Upload Your Product Files

The first step is to simply fill in your information and upload your CAD file. This helps us to create a 3D model of your desired part or prototype. |

2.Quote & Design Analysis

Within 24 hours, we will provide you with a quote and feedback. This ensures that your project is feasible and provides you with an accurate cost estimate. |

3.Order & Start Production

Once you have approved the quote and design, we will make PI for your payment and start production on your CNC prototype or CNC machined parts get start now ! |

WHAT DO YOU NEED TO KNOW ABOUT ?______________________

cNC MACHINING FAQs

Q1.How do I get a manufacturing quote?

Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples.

Krosino gives you instant pricing and lead times for your custom parts.You could send the drawings online or to our mailbox :charles911(at)sinomechatronic.com.

In most cases, we respond Quotation within 24 business hours of receiving an RFQ. If the quote is delayed, we will notify you as soon as possible.

Q2.Who is responsible for my project?

Each project is assigned a sales staff and our project engineer, who will be there from project launch to the delivery of your parts.

Q3.What file types do you support for an instant quote?

Krosino prefers 3D CAD file in format STEP, IGS, STL.

2D CAD drawings with reference dimensions in format DWG and PDF.

Q4.What is your MOQ(minimum order quantity)?

No minimum order quantity requirements.MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Our services can support your scale from one-off prototypes all the way to mid- and high-volume production.

Q5.What is the production period?

It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers' requirement

by adjusting our workshop schedule.

Q6. Is it possible to know how is my product going on without visiting your company?

In accordance with your request, we will offer a detailed products schedule and send weekly reports with digital pictures and

videos which show the machining progress.

Q7.What are the shipping terms?

Our standard terms are ExW/FOB/CFR for rapid prototyping and regular production orders. We also offer terms of Delivery At Place(DAP) by Fedex/UPS/DHL Express, customers are responsible for import duties and fees associated with international shipping. Customers also have the option to use their own shipping accounts (e.g. DHL,FedEx or UPS) during checkout if applicable.

Q8.What tolerances can Krosino's CNC machining achieve?

There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to: part size, design geometry,

materials, surface finish.

Krosino's general tolerance is applied to ISO 2768 (medium) for machined plastic and ISO 2768 (fine) for machined metals.

Q9.How does Krosino ensure the quality of my parts?

Krosino takes a proactive approach to customer's quality concerns from the initial communication, providing cost-effective and rationalized advice from designs, materials, production processes, manufacturability, etc.

Once your order is confirmed, we will perform a full Design for Manufacturing (DFM) review to point out any issues that may affect the quality of your parts.

We have the ability to share inspection data with you in real-time so we can work together to address any quality issues you may have during production. All incoming materials will meet your design specifications.

Even if you received defective parts ,you could show us directly , we will check and negotiate a quick solution to solve the problem . Including but not limited to :free remaking the defective parts(if only a little defective parts),free remaking full order or refund the money directly (if defective parts more than 60%)