CNC METAL MACHINING

METAL MACHINING SERVICE

Metal Machining Parts are widely used in the mechanical manufacturing industry. Krosino provides higher machining accuracy, faster machining efficiency and more consistent machining quality for our customers by CNC metal machining serivce .

GET AN INSTANT QUOTE | Metal MACHINING

GET AN INSTANT QUOTE | Metal MACHINING

Choose a Realiable Supplier

KROSINO provides a variety of metal machining services such as steel ,stainless steel,aluminum,alloy,titanium that can be customized to meet the specifications of your product design.

What Do You Know About CNC Metal ?

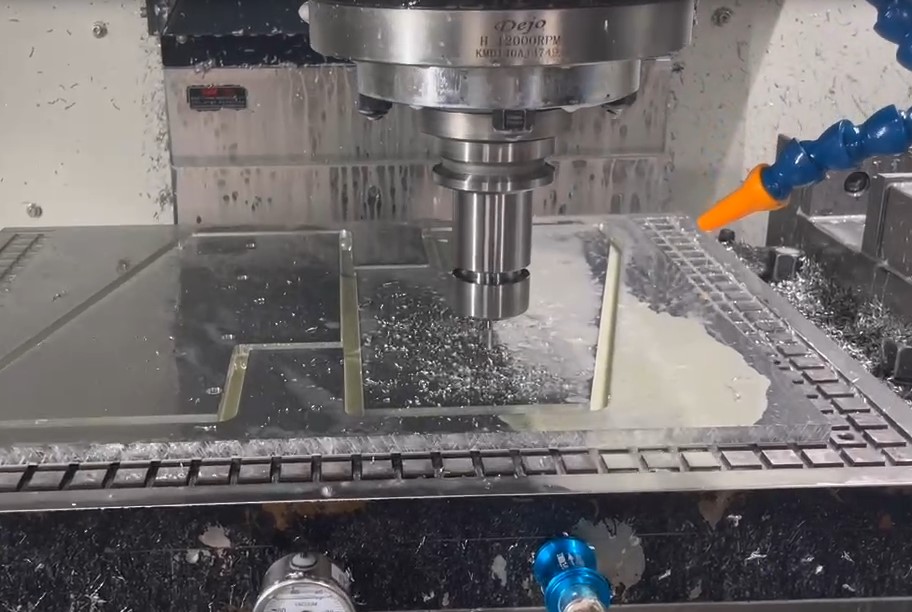

Metal machining is a controlled process of cutting a piece of raw material and creating a desired final shape and size is known as machining. Metal machining uses milling machines, lathes, drill presses and various other machines to manufacture shapes in a wide variety of metals.Through the process of removing metal material, the CNC machine cut the desired shape, size, and surface finish to meet the specifications of product designs and engineering drawings.

Our CNC metal capabilities include prototyping and low-volume custom machining, with particular expertise in CNC aluminum machining, CNC stainless steel machining as well as other metals such as magnesium, zinc, titanium, steel,and a variety of secondary operations and surface treatments.

Why Use CNC For Metal Machining?

1.The accuracy of the CNC machine ensures consistent product quality. The process is more precise than manual machining and can be repeated in exactly the same manner over and over again. Depending on the material and its strength and hardness, CNC machining will yield different results and finishes.

2.All processes can be set up using adjustable fixtures and automated machine positioning systems, making it possible to respond to production schedules with greater flexibility and productivity. Production is completely automated by the program and the machining process is continuous. Increased production speed and increased efficiency..

3. The automation technology development has made the machining processes are mainly controlled by computers or robots, which avoids the process of long processes in production lines. Also, it reduces hardware investment and workload, saving a lot of time and effort, and thus reducing production costs.Due to technological developments, machining in the manufacturing industry has been automated.

2.All processes can be set up using adjustable fixtures and automated machine positioning systems, making it possible to respond to production schedules with greater flexibility and productivity. Production is completely automated by the program and the machining process is continuous. Increased production speed and increased efficiency..

3. The automation technology development has made the machining processes are mainly controlled by computers or robots, which avoids the process of long processes in production lines. Also, it reduces hardware investment and workload, saving a lot of time and effort, and thus reducing production costs.Due to technological developments, machining in the manufacturing industry has been automated.

Different Machining For CNC Metal Parts

CNC Milling: Milling machines use rotary tools to cut away at the material, with instructions originating from the program file, to create the part design.

CNC Turning:CNC turning is a manufacturing process that involves holding bars of material in a chuck and rotating them while feeding a tool to the piece to remove material until the desired shape is achieved. This is a form of CNC metal machining that involves the use of lathes and cutting tools to remove unwanted metal material from rotating parts. CNC turning is ideal for creating cylindrical pieces.

Laser Cutting:Laser cutting is a type of thermal separation process. The laser beam hits the surface of the material and heats it so strongly that it melts or completely vaporizes. Once the laser beam has completely penetrated the material at one point, the actual cutting process begins.Most kinds of metal can be cut with a laser cutter. Steel and iron are the most popular metals cut in this way. The thickness of the metal will depend on the size of the laser cutter, but some can work with thicknesses of up to 30mm.

Drilling:Drilling is to create a round hole on the metal workpiece. A drilling press, a tapping machine or a milling machine all can be used to perform this process. The boring process involves enlarging existing cast or drilled holes; The reaming is used to enlarge a previously drilled hole to a very precise diameter.

Milling involves the use of multi-point rotary tools to remove material from a workpiece. The features of milling metal processes include pockets, slots, flat surfaces, complex contours, and chamfers. The function and coordinates of the cutter are controlled by the milling machine's computer, with minimum human input needed to complete manufacturing.

CNC Turning:CNC turning is a manufacturing process that involves holding bars of material in a chuck and rotating them while feeding a tool to the piece to remove material until the desired shape is achieved. This is a form of CNC metal machining that involves the use of lathes and cutting tools to remove unwanted metal material from rotating parts. CNC turning is ideal for creating cylindrical pieces.

Laser Cutting:Laser cutting is a type of thermal separation process. The laser beam hits the surface of the material and heats it so strongly that it melts or completely vaporizes. Once the laser beam has completely penetrated the material at one point, the actual cutting process begins.Most kinds of metal can be cut with a laser cutter. Steel and iron are the most popular metals cut in this way. The thickness of the metal will depend on the size of the laser cutter, but some can work with thicknesses of up to 30mm.

Drilling:Drilling is to create a round hole on the metal workpiece. A drilling press, a tapping machine or a milling machine all can be used to perform this process. The boring process involves enlarging existing cast or drilled holes; The reaming is used to enlarge a previously drilled hole to a very precise diameter.

Wire EDM:Wire EDM machining (Electrical Discharge Machining) is an electro thermal production process where a thin single strand metal wire, along with de-ionised water (used to conduct electricity) allows the wire to cut through metal by the use of heat from electrical sparks, while preventing rust.

KROSINO Metal Machining

The Krosino team and its partner factories are able to provide precision CNC metal machining services that can handle custom metal parts with tight tolerance requirements and complex geometry needs.

Our high power capacity and rigidity of machine tools ensure that almost any kind of the metal material can be machined.

Krosino combines our extensive industry experience with advanced manufacturing processes and machining equipment to create high-quality CNC metal parts and precision machined components.We are able to meet the needs of our customers across industries and manufacture custom machined parts according to customer specifications.

Our experienced machinists and engineerings are able to handle the needs of most manufacturing projects and provide fast turnaround times.

Our CNC metal machining capabilities allow us to produce precision metal parts with more complex shapes and tighter tolerance requirements. The multi-axis machining capabilities allow performing milling,turning,drilling,boring and threading at almost any angle.

Krosino also provides special surface treatment options for your CNC metal parts and an integrated finishing service to meet your needs.

Widely used metal materials including ALUMINUM6061, ALUMINUM7075,

ALUMINUM5052, ALUMINUM6063, ALUMINUM6082, ALUMINUM5086, ALUMINUM5754, STAINLESS STEEL304, STAINLESS STEEL316, STAINLESS STEEL201, STAINLESS STEEL301, STAINLESS STEEL303, STEE4140,STEEL4340,20#,45#,TITANIUM,COPPER,BRASS,ZINC, ETC.

Our high power capacity and rigidity of machine tools ensure that almost any kind of the metal material can be machined.

Krosino combines our extensive industry experience with advanced manufacturing processes and machining equipment to create high-quality CNC metal parts and precision machined components.We are able to meet the needs of our customers across industries and manufacture custom machined parts according to customer specifications.

Our experienced machinists and engineerings are able to handle the needs of most manufacturing projects and provide fast turnaround times.

Our CNC metal machining capabilities allow us to produce precision metal parts with more complex shapes and tighter tolerance requirements. The multi-axis machining capabilities allow performing milling,turning,drilling,boring and threading at almost any angle.

Krosino also provides special surface treatment options for your CNC metal parts and an integrated finishing service to meet your needs.

Metal Materials Suitable For CNC Machining

Widely used metal materials including ALUMINUM6061, ALUMINUM7075,ALUMINUM5052, ALUMINUM6063, ALUMINUM6082, ALUMINUM5086, ALUMINUM5754, STAINLESS STEEL304, STAINLESS STEEL316, STAINLESS STEEL201, STAINLESS STEEL301, STAINLESS STEEL303, STEE4140,STEEL4340,20#,45#,TITANIUM,COPPER,BRASS,ZINC, ETC.

How Does CNC Metal Machining Work?

CNC machining is a metal fabrication method. A high-efficiency automated CNC machines are running by a digitalised computer that automates, monitors, and controls the movement of an industrial machine for machining complex-shaped workpieces consisting of mechanical equipment and CNC systems. In large industrial plants, the computer is usually installed in the machines.The exact movements that this code controls depends on the type of CNC machine that is being used. CNC machining is a form of subtractive manufacturing, meaning that material gets removed (rather than added) during the production process. This means CNC machining starts with a block of material (called a blank), and uses fast-moving cutters to quickly carve away material and create the finished part.

The CNC system can control the machine tool according to different metal machining operations automatically changing tooling, selecting the spindle speed, feed, etc. So it can be completed continuously by drilling, boring, milling, reaming, tapping, and other processes.

The CNC metal process greatly reduces the workpiece clamping, measuring and machine tool adjustment, and other auxiliary setup time, which is suitable for machining more complex shapes, high precision, and repeatability requirements of the parts.

The CNC system can control the machine tool according to different metal machining operations automatically changing tooling, selecting the spindle speed, feed, etc. So it can be completed continuously by drilling, boring, milling, reaming, tapping, and other processes.

The CNC metal process greatly reduces the workpiece clamping, measuring and machine tool adjustment, and other auxiliary setup time, which is suitable for machining more complex shapes, high precision, and repeatability requirements of the parts.

Our company was founded in Tianhe District, Guangzhou on May 8, 2003

And these two England captains, in fact, were inextricably linked almost 10 years ago. They once attended the same school in London, England. The girl in this photo is now Harry Kane's wife.Beckham has witnessed Kane's growth in the past few years. He once said that Kane had earned the chance for the national team with his outstanding performances.